Components that can be epilamized (examples):

Components and lubricants from Dr. Tillwich GmbH Werner Stehr

Epilamization of axial contact washers in electric motors prevents collectors from creating collector paste.

Common practical problems due to wetting (starved lubrication)

Problems arising as a result of the migration or creepage of lubricants:

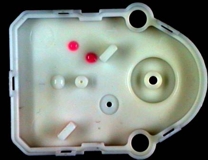

Photo on left: Housing from automotive instrument Upper half is epilamized. Photo taken in reflection contrast.

Typical processes involving damage occur: Starved lubrication due to bearing lubricants spreading. In these cases the oily component of the lubricant creeps onto the adjacent surfaces of the bearing housing and in time a significant amount of lubricant is lost; a point can be reached where the bearing is running dry and can fail. The field of DIY tools has produced a widely-known situation where the liquid greases for lubricating the gears wet all the components within the housing, resulting in a reduction of the actual repository lubrication by more than 80%. The subassemblies fail after less than one tenth of the service life expected of them. These large quantities of lubricant, which creep long distances in an uncontrolled and unwanted manner, can cause damage in another typical way: Starved lubrication in the porous bearings of a fan motor result in unpleasant noise, an increase in bearing temperature, and a failure of the motor after 2 years of use in the field.